Socket Weld Fittings

Home » Our Product » Pipe Fittings » Socket Weld Fittings

Our Product Range

Socket Weld Fittings

Socket weld fittings are a type of pipe connection commonly used in high-pressure, high-temperature systems. These fittings involve a pipe being inserted into a recessed area of a valve, fitting, or flange and then welded around the joint, creating a strong and leak-proof connection. This design ensures maximum strength and durability, making it ideal for industrial applications.

One of the main advantages of socket weld fittings is their ability to create solid, reliable joints that can withstand high pressure and thermal cycling. They are widely used in industries such as oil and gas, petrochemicals, power plants, and manufacturing. Their design minimizes the risk of leakage, making them an excellent choice for hazardous or high-pressure environments.

get in touch

Reach Out to Royal Forge & Fittings Industries for Product Information and Support

Get in touch with Royal Forge & Fittings Industries for expert assistance, detailed product information, and personalized support. Our team is ready to provide the solutions you need with professionalism and prompt service.

Socket Weld Fittings for High-Pressure Applications

Socket weld fittings come in various types to accommodate different piping needs. Common types include socket weld elbows (used to change direction), tees (for branch connections), reducers (for connecting different pipe sizes), and couplings (for joining straight sections). Each fitting is designed to maintain flow integrity and structural reliability.

At Royal Forge & Fitting Industries, our socket weld fittings are manufactured using premium materials such as stainless steel, carbon steel, and alloy steel. All products meet international quality standards like ASTM, ASME, and ANSI. Our strict quality control processes ensure every fitting delivers exceptional performance and longevity in demanding conditions.

Features Of Socket Weld Fittings

- High Pressure Strength

- Leak-Proof Joint Design

- Excellent Dimensional Accuracy

- Corrosion & Heat Resistance

- Strong Mechanical Performance

Application Of Socket Weld Fittings

- Oil and Gas Industry

- Petrochemical & Chemical Plants

- Power Generation Plants

- Pharmaceutical & Food Processing

- Shipbuilding & Marine Applications

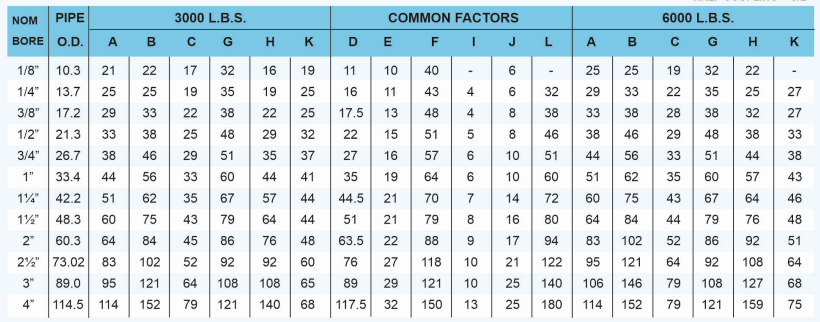

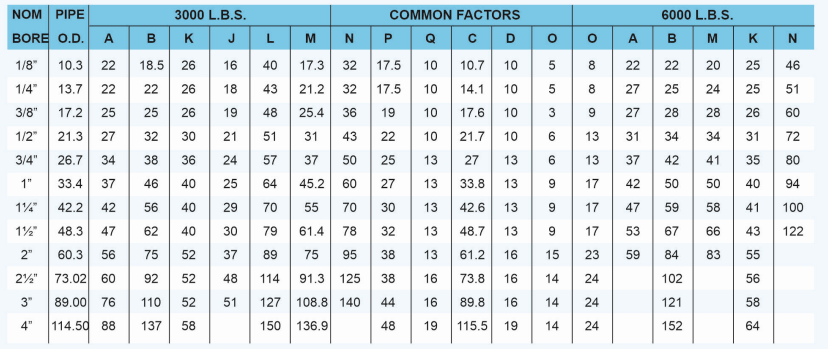

Specification Of Socket Weld Fittings

| Stainless Steel | ASTM A182 F304/304L/304H/316/316L/317/317L/321/310/904L etc. |

| Carbon Steel | ASTM A105/A105N/A694 F42/46/52/56/60/65/70/A350LF3/A350LF2 etc. |

| Alloy Steel | ASTM A182 F1/F5/F9/F11/F22/F9letc. |

| Others | Monel, Nickel, Inconel, Hastalloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminium, High Speed Steel, Zinc, Lead etc. Elbow, Tee, Union, Cross, Coupling, Cap, Bushing, Plug, Swage nipple, Welding Boss, Hexagon Nipple, Barrel Nipple, Barrel Nipple, Welding Nipple, Parraler Nipple, Street Elbow, Hexagon Nut, Hose Nipple, Bend, Adapter, Insert, Cross, Weldolet, Elbowlet, Sockolet, Thredolet, Nipolet Letrolet etc. |

| Size Range | 1/8" NB to 4" NB (Socket weld) |

| Thread Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

Dimensional Tolerances of Socket Weld Fittings

| Parameter | Tolerance |

| Outside Diameter at Welding End (OD) | ± 1% or ± 0.5 mm (whichever is greater) |

| Center-to-End (Elbows, Tees) | ± 1.5 mm |

| Overall Length (Couplings, Reducers) | ± 1.5 mm |

| Wall Thickness (WT) | ± 12.5% of nominal thickness |

| Socket Bore Diameter | ± 0.3 mm |

| Socket Depth | ± 0.5 mm |

| Facing Finish (Flat Surfaces) | 1.6 – 6.3 Ra (Surface Roughness in µm) |

| Concentricity (Bore vs. OD) | ± 0.8 mm max |

| Angularity | Max 1° deviation |