Butt Weld Fittings

Home » Our Product » Pipe Fittings » Butt Weld Fittings

Our Product Range

Butt Weld Fittings

Butt weld fittings are essential components in piping systems, designed to create strong, permanent connections between pipes. These fittings are joined by welding the ends of the pipes directly to the fitting, resulting in a smooth, continuous flow path that minimizes pressure loss and enhances structural integrity. This method of joining is particularly beneficial in high-pressure applications where leak resistance and mechanical strength are critical. Common types of butt weld fittings include elbows, tees, reducers, and caps, each serving a specific purpose in directing or modifying flow within a pipeline.

One of the primary advantages of butt weld fittings is their ability to provide seamless connections. When welded, the joint becomes as strong as the pipe itself, making it ideal for applications in industries such as oil and gas, chemicals, water treatment, and power generation. The smooth internal surfaces of butt weld fittings also help reduce turbulence and erosion, which can lead to longer service life and reduced maintenance costs. Moreover, these fittings can be manufactured in a range of materials, including carbon steel, stainless steel, and alloys, allowing for compatibility with various media and operational conditions.

get in touch

Reach Out to Royal Forge & Fittings Industries for Product Information and Support

Get in touch with Royal Forge & Fittings Industries for expert assistance, detailed product information, and personalized support. Our team is ready to provide the solutions you need with professionalism and prompt service.

The Role of Butt Weld Fittings in Pipeline Design and Construction

The installation of butt weld fittings requires skilled labor and adherence to specific welding techniques to ensure the integrity of the joints. The process typically involves cutting the pipe to the desired length, fitting it against the fitting, and then using a welding method such as TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) to create a robust bond. Post-welding inspections, such as radiographic or ultrasonic testing, may be performed to ensure the quality of the weld and to detect any potential defects. Properly installed butt weld fittings can significantly enhance the safety and efficiency of a piping system.

In addition to their performance benefits, butt weld fittings can be customized to meet specific project requirements. Manufacturers often provide different schedules (wall thicknesses), diameters, and finishes to cater to diverse applications. Whether for high-temperature or corrosive environments, the versatility of butt weld fittings makes them a popular choice in many industrial sectors. Their seamless design and strength provide engineers and designers with confidence in the reliability and longevity of their piping systems.

Features Of Butt Weld Fittings

- Seamless Construction

- High Strength and Durability

- Variety of Configurations

- Material Options

- Versatile Sizes

Application Of Butt Weld Fittings

- Oil and Gas Industry

- Chemical Processing

- Power Generation

- Water Treatment Facilities

- HVAC Systems

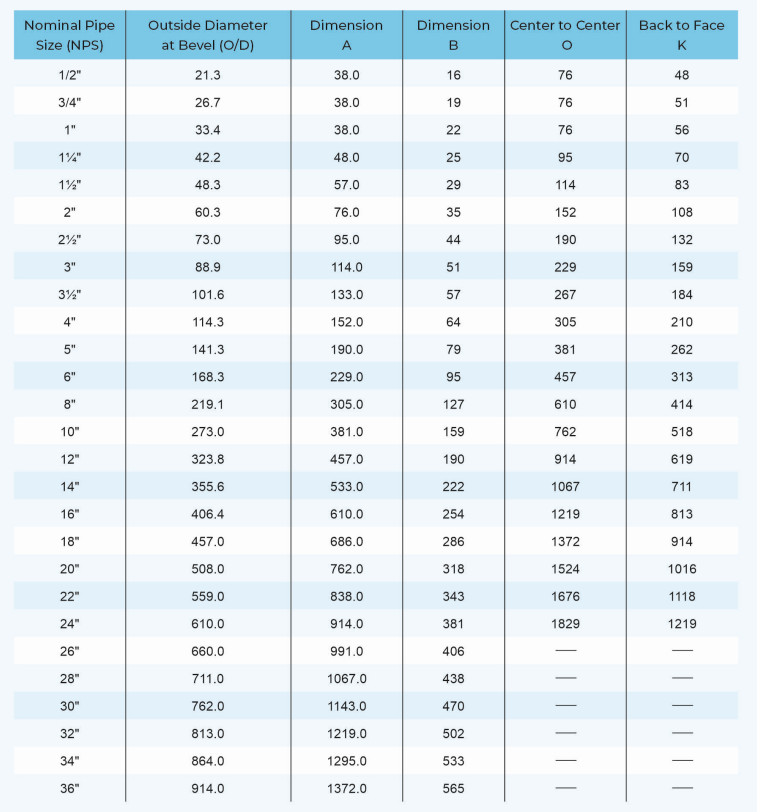

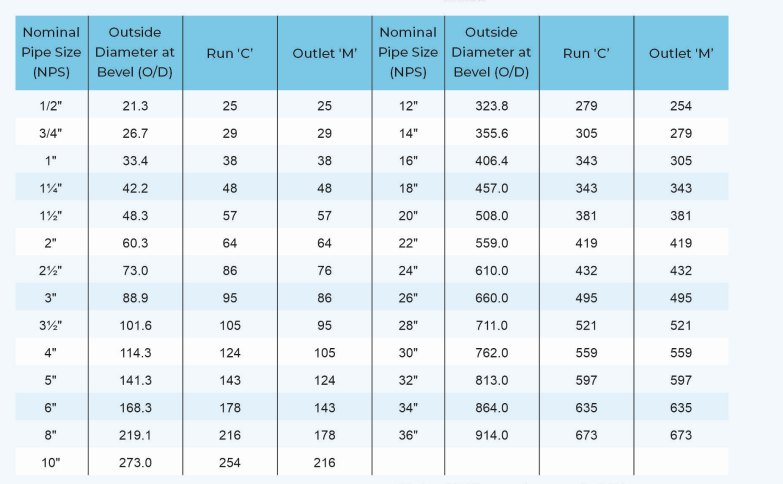

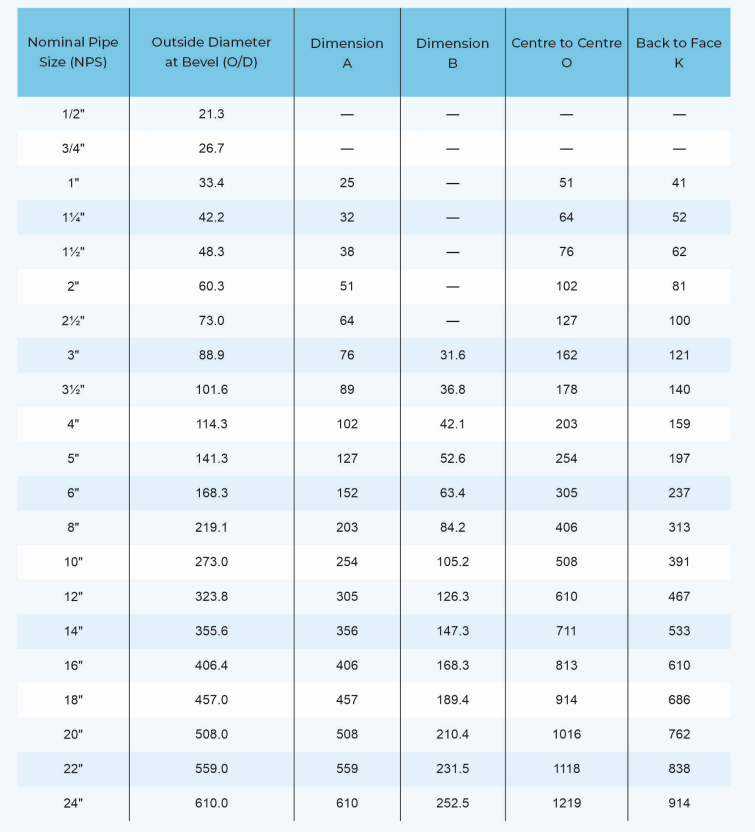

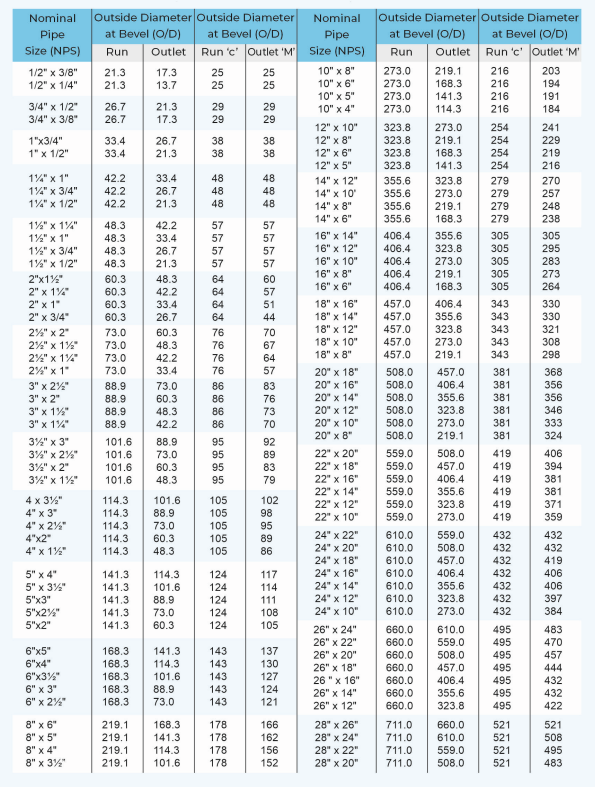

Specification Of Butt Weld Fittings

| Standards | ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43 |

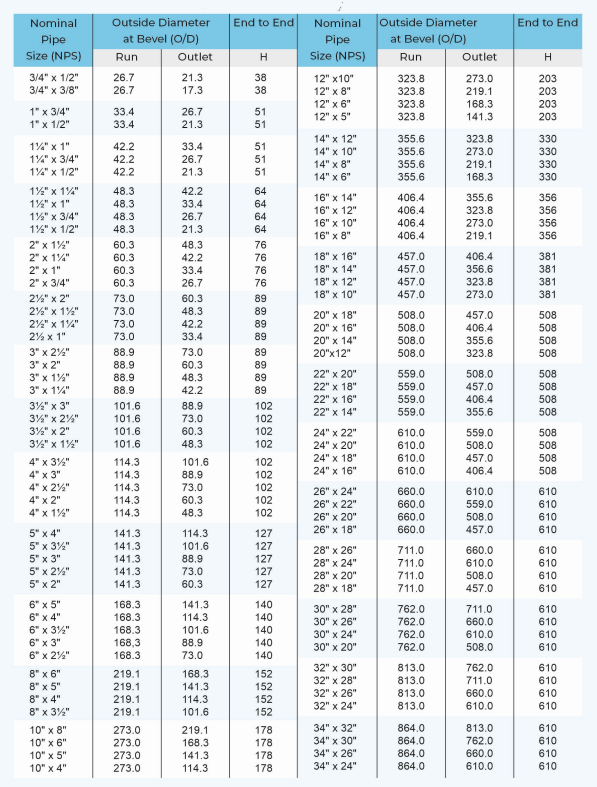

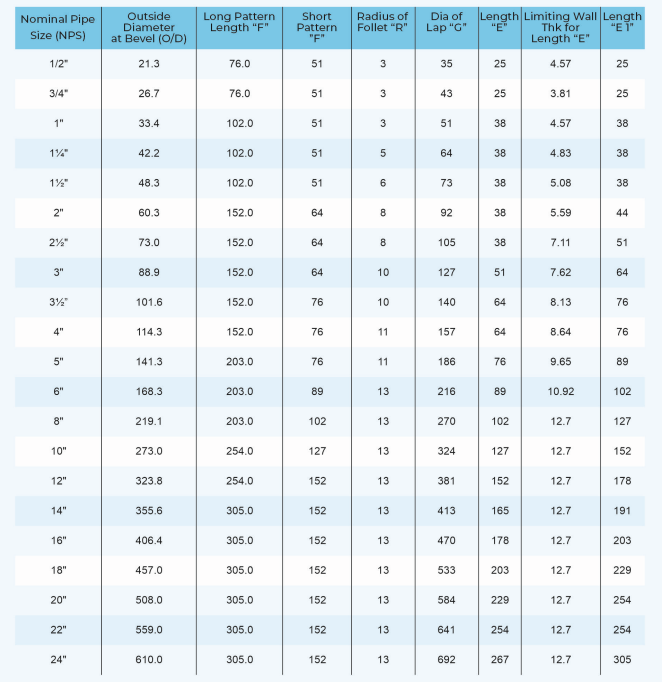

| Size | 1/8" NB TO 48" NB. (Seamless & 100% X-Ray Welded, Fabricated) |

| Thickness | SCH: 5s, 10s, 40s, 80s, 10, 20, 40, STD, 60, 80, XS, 100, 120, 140, 160, XXS, Custom Thickness. |

| Dimension | B16.5, BS 4504, ΕΝ-1092, |

| Specialize | Long Bend with Radius - R = 3D, 5D & 10D Pigabble Bend & As per your drawing |

| Value Added Service | Polish (Electro & Commercial)Heat Treatment |

Dimensional Tolerances of Butt Weld Fittings

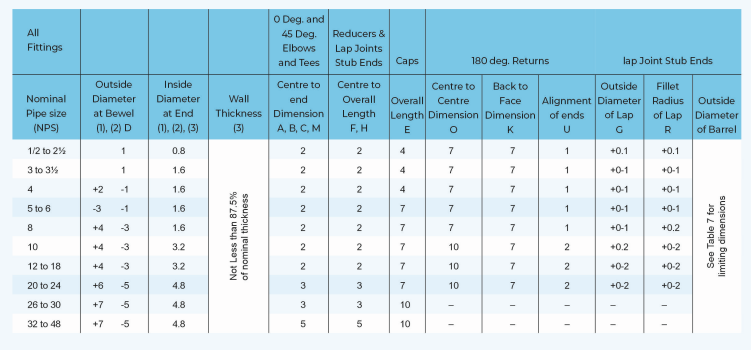

| Dimension | Nominal Size (inches) | Tolerance |

| Outer Diameter | 1/2" - 24" | ±1/16" or ±1.5% (whichever is greater) |

| Wall Thickness | Up to 1" | ±1/16" |

| Length | Standard Sizes | ±1/8" |

| Center-to-Center Distance of Outlets/Branches | Up to 12" | ±1/16" |

| 12" - 24" | ±1/8" | |

| Bolt Hole Diameter | 1/2" - 1.5" | ±1/32" |

| 2" - 24" | ±1/16" | |

| Face Flatness | - | Typically within 0.005" per 12" length |

| Ends Preparation | - | Prepared according to standards (e.g., beveled for welding) |

| Weight | Varies by size and material | Calculated per ASME/ANSI Standards |